Address: 70 Patterson Rd, Bentleigh VIC 3204

From a chat with Leon in 2022 that’s been edited

In conjunction with the City of Glen Eira as part of the Talking Shops exhibition

I grew up in West Ukraine in the City of Lviv and played and performed on the violin from five and a half years old, until 20.

Growing up, I would go to a musical school – after normal school – four days a week for about eight years. I was playing classical music – Tchaikovsky, Bruch, Mendelssohn, and so on.

I went to the College of the Arts for four years and graduated as an orchestral performer, but I changed my occupation to violin making. People tend to ask why. My problem was that I was looking for something more suitable for me to realise my understanding of sound. I liked playing, but I found it difficult performing in front of people.

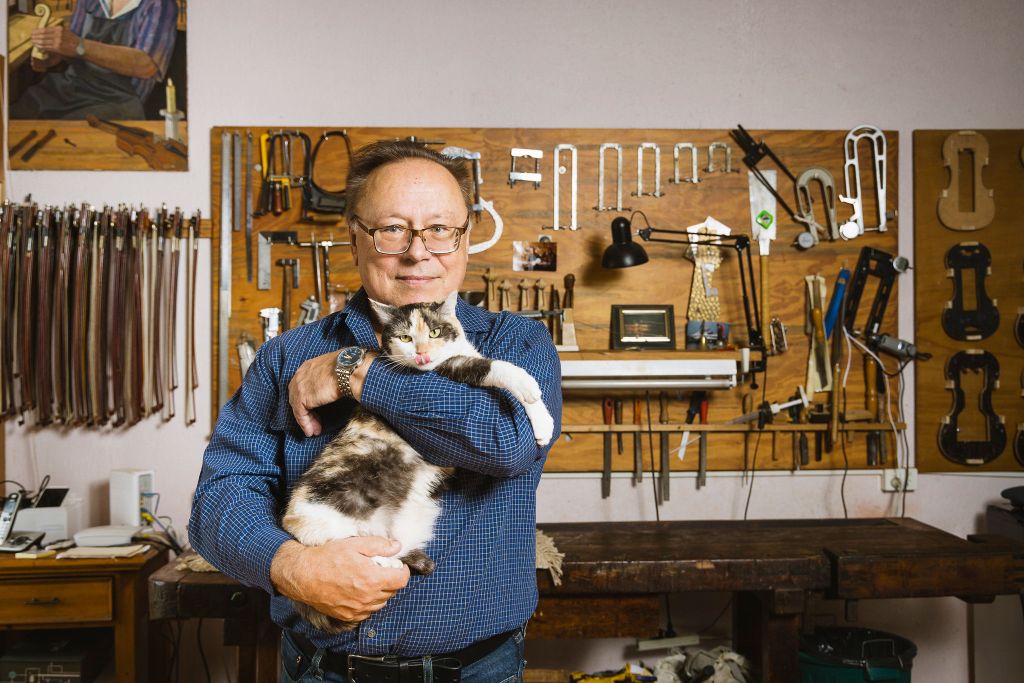

So I decided to become a violin maker. I went to the shop in the city of Lviv in West Ukraine – which had a strong, classical music tradition – and started in a violin making workshop as an apprentice. From 1980-1990, I had my own workshop, where I repaired and made violins. I migrated to Australia and worked from home until around 1994.

I then opened the workshop in Bentleigh, and – with a few stops in between – I’ve worked in this space from then until now.

About 33 years working in Melbourne.

In 1996, I closed the shop and worked in Cremona, Italy for two years.

I worked with a friend, Valerio Prilipco – pupil of the renowned G.B. Morassi – and made instruments in his workshop. I was thinking about coming back to Australia, but I received an invitation to work in a violin shop in Montpelier, France. I spent half a year there, learning their method of making violins, before coming back to Australia and reopening the workshop in 1998.

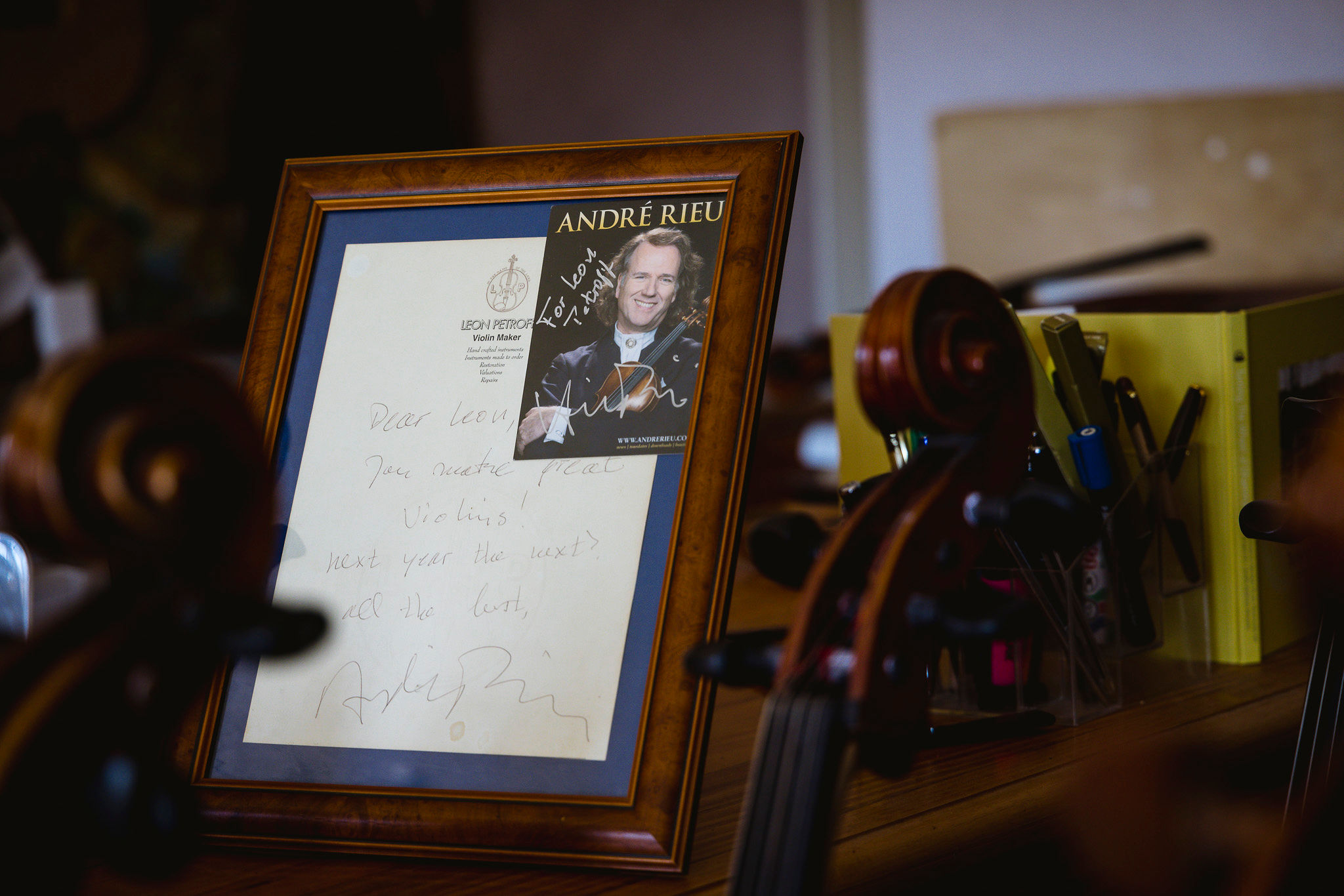

Over the years, as I gained more skills and experience, I started conducting lectures and working with different masters. For instance, André Rieu invited me to check his orchestra’s instruments. When he came to Brisbane or Melbourne, I’d inspect the violins. It’s quite difficult work, because I’m not in the workshop with all my tools.

I can still play on the violin, but generally I’m more interested in violin making, repairing, and selling. I also work as a violin dealer. Now, I’m probably producing two or three instruments each year.

I’ve also specialised in working with professional, rather that amateur players.

If I wasn’t making violins for a year, for example, I’d likely lose the feeling.

It requires an extensive knowledge and constant practice. For instance, Italy has different cities, or schools, known for making violins – such as Cremona, Brescia and Venice– all of which involve different outlines, measurements inside the instruments, thickness around the plates and so on.

How I’ve learned is not just by being in Cremona or Montpelier, but by repairing instruments. Some famous instruments have been in my studio, including Nicola Amati 1650 and Antonio Stradivari 1730 “Tritton” violins.

In 2006, I went back to Montpelier and spent another few months working with a renowned violin maker, making violins in her workshop.

She mostly worked with cellos, and her husband mostly worked with violins.

I initially moved to Melbourne at 33 years old because my sister – who is a violinist – was here, as well as my mum.

My brother in law is also a violinist for the Melbourne Symphony Orchestra, and performs on a violin I made. Coming from the Soviet Union, my family chose Australia as their home, as it is one of the three places – alongside Canada and the US – where lots of people migrated.

When I arrived in Australia, I spoke no English and – even after building my reputation and skills working overseas – developing a career as a violin maker was a slow and steady process. Building a community was also a bit of a slow process. I went to TAFE and studied English for the first six months, but that wasn’t enough. Mostly, I learned the language by talking to people

From 1996, people from the Melbourne Symphony Orchestra started coming into my shop, and they came back when I returned to Australia in 1998.

I’ve completed a number of restorations of antique violins. I’ve also mostly persisted with the Cremona tradition and method of making violins. After 35 years, I can use my experience to explain to people what’s going on.

For 400 years, not much has changed in terms of the techniques involved in making violins.

If you know how to make violins, it’s a step-by-step process. Once you’ve worked long enough and become more confident in your ability, you can use your intuition and experience, rather than just follow a rigid process.

The interesting thing is, when customers bring their instrument to me for repairs and say the violin strings are a bit tight or the instrument sounds quiet, it’s about problem solving to see what’s happened, and how I can fix the issue.

After 45 years in business, I’m starting to learn what’s going on.

In my training, I was learning how to make violas and cellos as well as violins.

The violin and viola are quite close, but with cellos it’s different. It has different proportions and thicknesses. It also has a different timbre density. For string instruments, you have to find the relationship between the belly and the back. The belly is the heart that pumps the air from the strings to the back. The back responds to the top, with the sound going out of the holes in the instrument. It needs a special tension – and the requirements are different, depending on the type of instrument.

A good maker can understand nuances regarding density and timber, and can make violins that are tailored to people and performances.

If you’re doing a job like this, it requires intense concentration and precision.

Making violins is also about the art, rather than just the sound.

Across Australia, there aren’t many people making violins professionally by hand. I produce 2-3 instruments per year, because that’s what I have time to do. I mostly focus on selling – which is my main cash flow. Repairing, servicing, and selling are the biggest parts of my job, not necessarily making instruments.

I’ve had an apprentice, but the process was quite difficult. You must spend a lot of time with another person who’s working with you. Violin making starts with shaping the knives and tools, and for that you have to go to school.

After that you can learn the fine art of making violins.

I don’t want to teach those basic skills, but in terms of the artistry and style, I’m happy to teach what I know.

This type of business requires a lifetime of knowledge and a precise obsession.

But it’s very rewarding. I’ve repaired instruments that subsequently produce a stronger or more powerful sound, which have helped to create a better orchestral performance.

It’s a finicky job that requires working with your hands and on your feet, but as long as my health gives me an opportunity to do this, I’ll do it. It’s not a hard job – but it requires a lot of concentration. When you’re in the zone, you need to focus on what you’re doing. I can’t think about the money or what I’m having for dinner or whatever.

Going to my boat and fishing is my other passion. It allows me to relax. In the middle of the ocean, I can be in an environment where I’m not thinking about violins. I try to go out twice a month. That’s enough for me. It’s a different thing to do.

But while I have my eyes, my ears, and hands, I’ll never stop doing this.

Written by Aron Lewin, with all photos by Tatiana C.C. Scott

talesofbrickandmortar@gmail.com