Address: 802/804 Glen Huntly Rd, Caulfield South VIC 3162

From an interview with Julian in 2020 that has been edited.

In conjunction with the Glen Eira City Council as part of the Talking Shops Exhibition

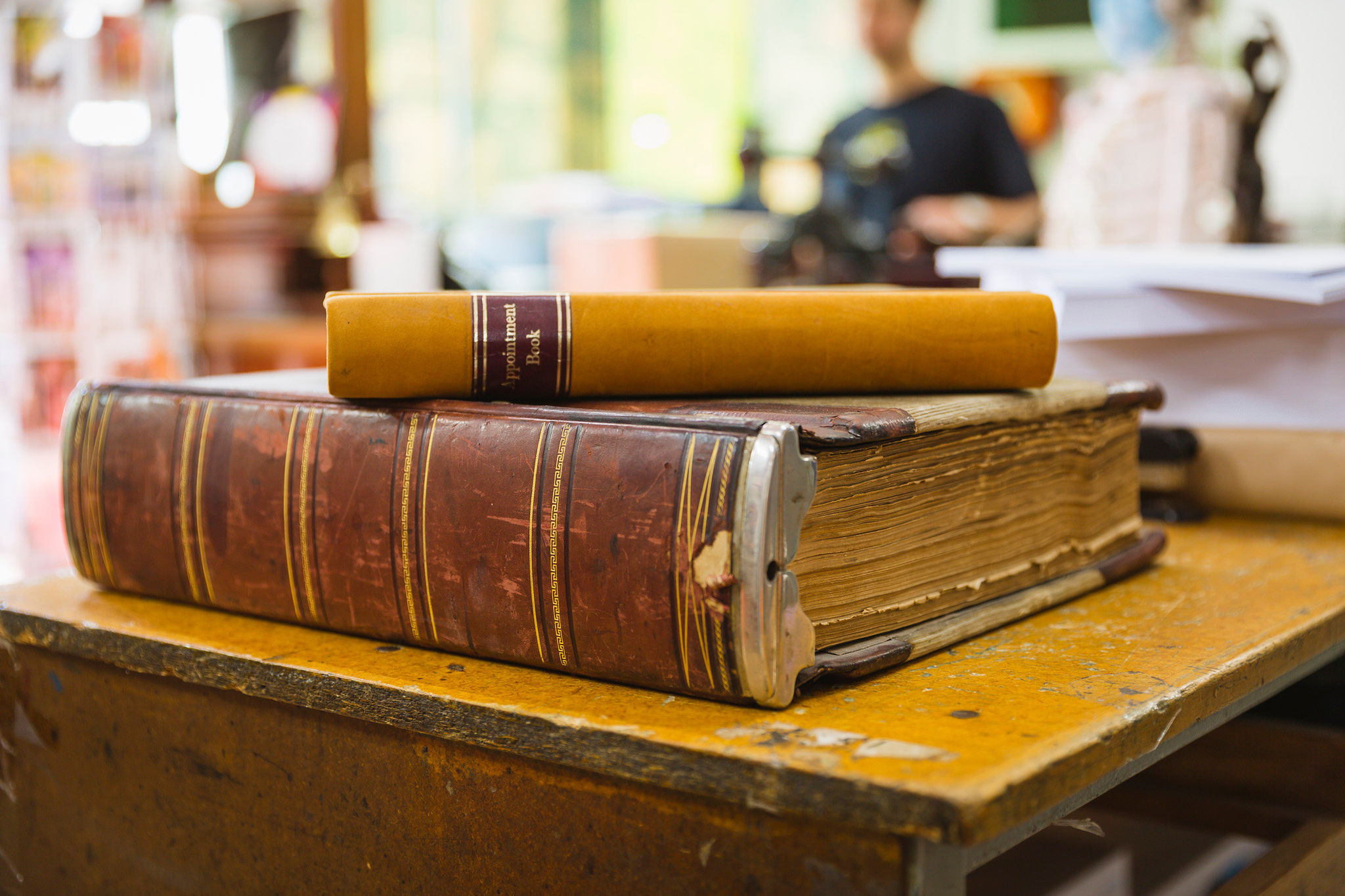

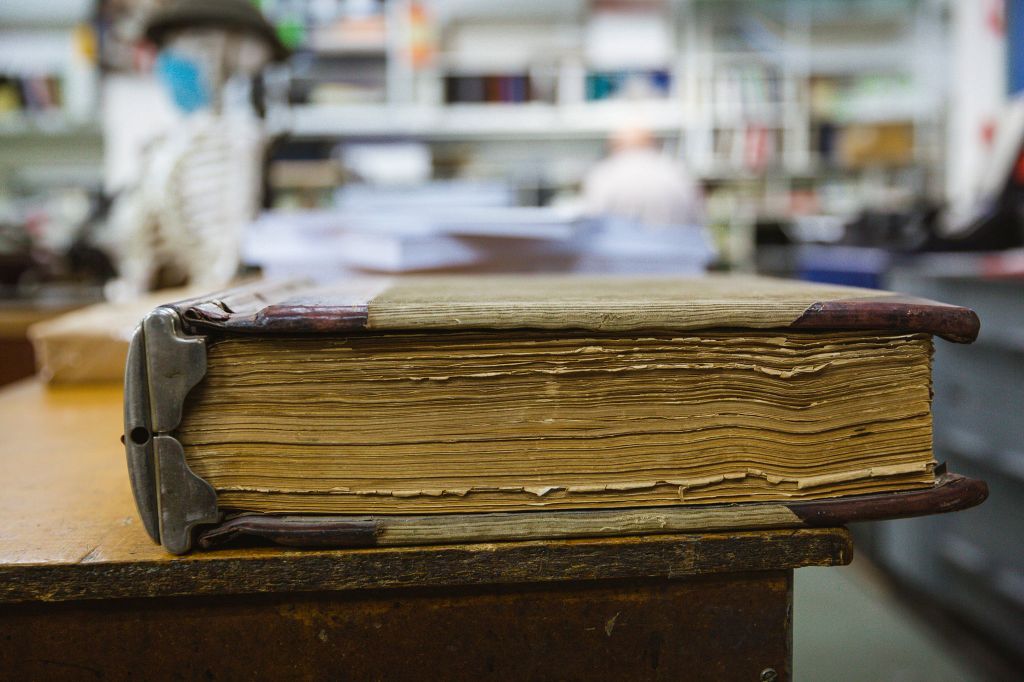

Whites Law Bindery has been operating in Melbourne for over 45 years now.

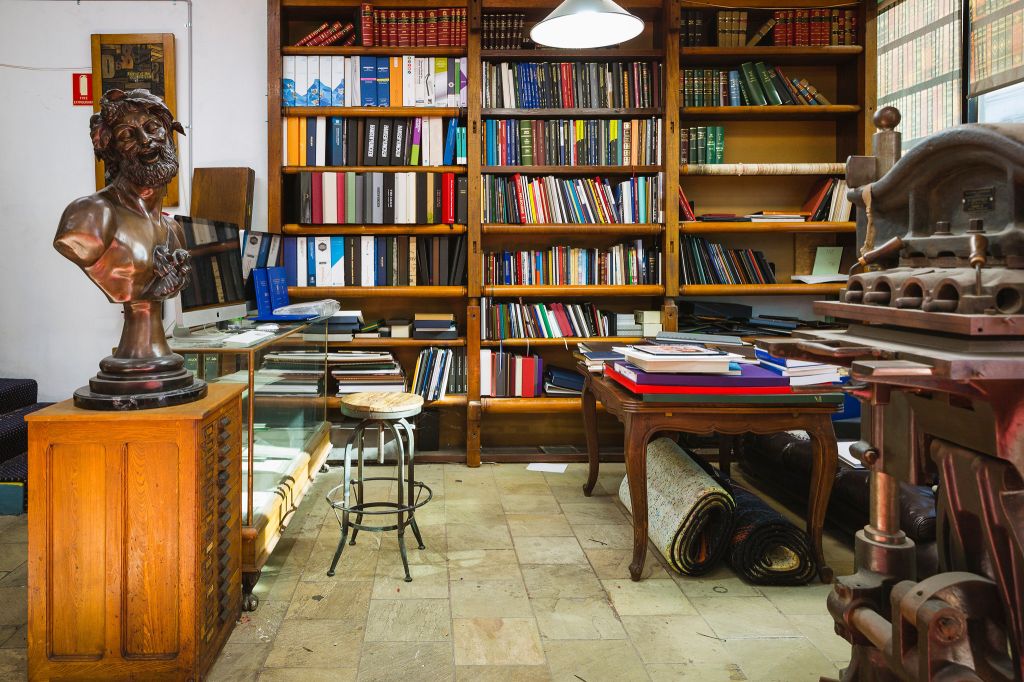

We are a full service bookbinder. We’re one of the last ones in Melbourne, if not all of Australia. We specialise in hard-case binding and high-end presentation work, but we also do all sorts of other things like boxes, student jobs, menu covers, ring binders and folders.

The business started out of college. The owner – who is also my uncle – had a passion for books and took it on as a hobby. He took a night-course, worked in the trade and realised that there was a gap in the market to satisfy binding for the legal industry. He went door to door speaking to lawyers, getting their legal binding done and conducting the work at home.

He set out on his own then opened up a shop in Ormond. He employed a number of binders and the business grew.

He has won a number of awards for hand bookbinding.

There’s been different incarnations of the business.

My uncle opened Law Bindery, then it merged with a stationery company called White’s Printers and Stationers. We’ve taken on a number of different binders over the years but the two that have stuck in the name are White’s Law Bindery.

Melbourne has traditionally been the home of printing in Australia and, at the time, there was a massive book-binding industry with different firms serving the market. The niche of our business was law books, but it quickly branched out into all sorts of other products – stationery products, library binding and so on.

Bookbinders offer all sorts of different products and you can’t make money just doing one thing.

We were only in Ormond for a few years before we moved up the road to Glenhuntly Rd in Caulfield South.

At the time Caulfield South was the geographical center of Melbourne, and my uncle realised that it would be a good place to move into a larger premise. We were up the road, then about 25 years ago, we moved into our current premises. Each time the business has moved it’s been because we needed more space to expand.

The reason that the owner was able to get customers in from the get-go was that he pounded the pavement, knocked on doors and was really passionate about his craft. Something the business has focused on from its inception was an emphasis on quality. When you’re knocking door-to-door and trying to drum up work you can’t fake that.

For a few years the business was just the owner in a workshop, but it’s grown steadily over the decades.

There’s 11 staff now, which is a bit down from our peak.

My uncle is a voracious reader.

He’s passionate about books as well as the craft of bookbinding. He always tries to instill a sense of building something beautiful.

It’s not uncommon to find my uncle in his office reading family histories and war journals. We have bound a ton of really incredible stories over the years. Unfortunately, we don’t have time to read them all, but I know that he takes great pride in leafing through the pages and reading stories that we’ve been privileged in helping tell.

And the work is constantly changing. It’s radically different now to what it looked like years ago. I wasn’t here at the time, but we used to produce thousands of books for the army and government, and we bound acts of Parliament. We would do massive jobs, which has changed a lot. Now it’s predominantly binding short runs.

It’s more passion driven which suits us because many of those jobs weren’t focused on the things we do well now.

Making a book is quite a process from start to end.

Most of the work in writing a book is done before it gets to us.

Once it gets to us, we take it over to the computer and figure out how to bind it. If we’re section sewing the book, we might print it in nested saddle stitch booklets. Those go through our printing press after we proof the file.

From there, the booklets go upstairs to Kelly who folds and collates the sections into a book block. She takes it to the sewing machine and sews it together. The book block then goes to the bench to be glued-up, end-papered and calicoed on the back, before being set aside to dry.

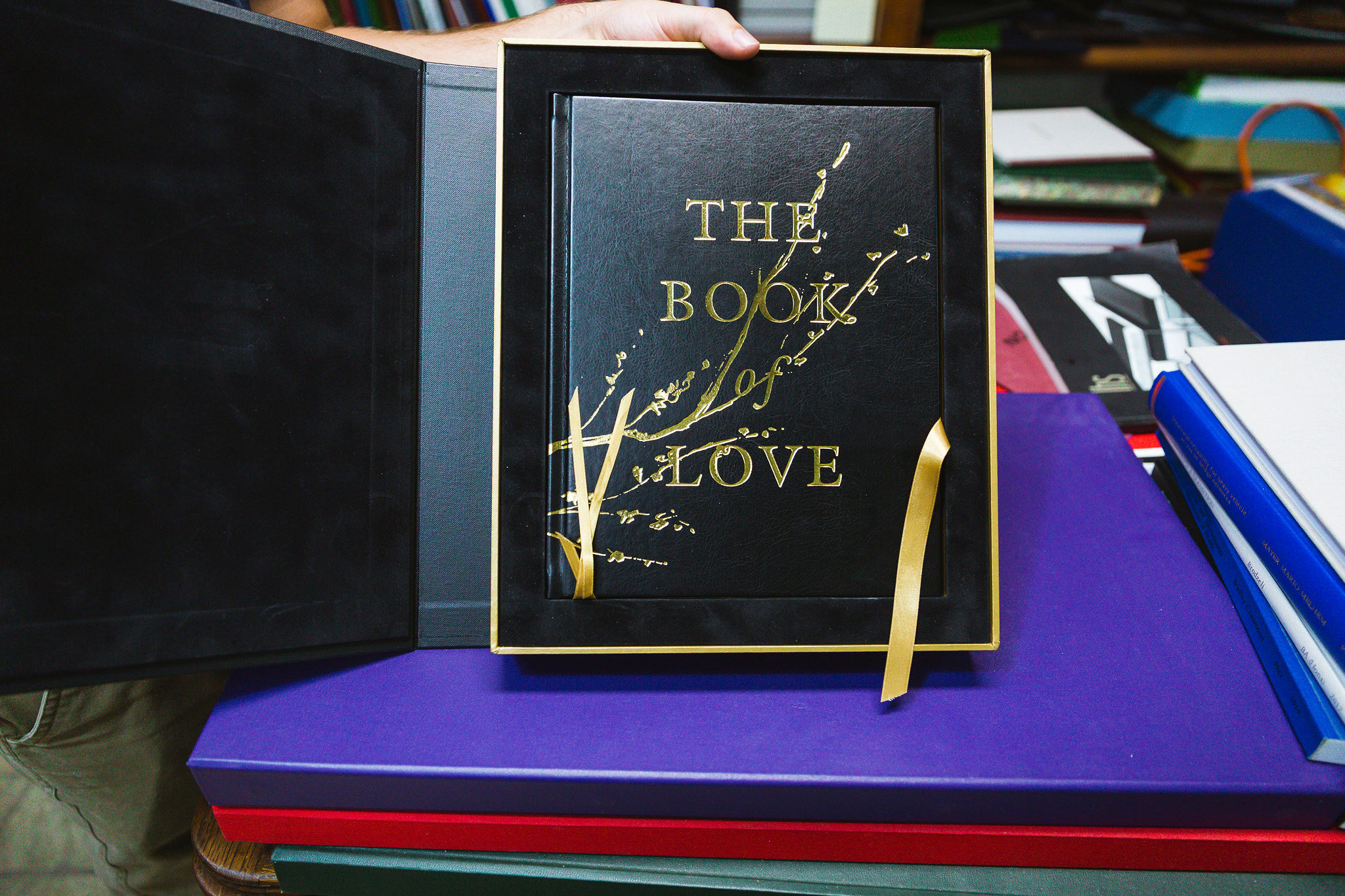

In the meantime, someone will size up the case, cut boards and cloth for the book block and make the cover. It will be checked against the book block to make sure that it’s the right size. If there’s any embellishment on the cover it will go on for foil stamping or printing. We make all of our own foiling plates in-house and do all of our foil stamping. Then you apply the embellishments to the cover before it goes onto the book block. The book block gets trimmed, then we glue the book block onto the case and leave it under weights until it dries.

If we’re lucky, that can all be achieved in about 24 hours. If we’re doing hundreds or thousands of books – like we might do for the Victorian court services – that can take two months to do. There’s many steps, but each of the steps depend on what the job is, and the product we’re making.

Each job is different, and a large part is thinking about how you’re going to get to the end and working backwards so you understand every step.

I came to the business about 12 years ago.

I started working upstairs on the bench gluing things together. Over my time here, I’ve slowly gained more skills. Now I run our production department and do most of the customer service as well. I’ve also worked a little bit in the bookbinding side of things.

I started working here just after moving from Colorado to Australia. I studied International Relations in the United States, then I got a Master’s at ANU studying finance. I did not anticipate that I would still be working here. I am not trained as a bookbinder or as a printer but this place has a tendency to get under your skin.

Most of the people have actually been here longer than I have: 20, 30 or 40 years. I have been here 12, and I don’t think I’ll be leaving anytime soon.

It’s an interesting place to work.

I don’t do much handwork so to speak.

But, for many people here handwork is really important.

Everything they do is with their hands. From Ian, who’s a fourth generation bookbinder all the way through to Kelly, who does all of our sewing. There’s great dexterity in what we do.

And I’m incredibly fortunate to work in a family business. I’m not the first niece or nephew to have worked here. In fact, I think I might be the fifth or sixth. The owner has encouraged family members to come into the business and give it a go. It certainly isn’t for everyone because it’s hard work, but being a family business provides a certain amount of familiarity and warmth.

While I’m technically the last remaining family member working here, I think everyone sees us as a family because we’ve all been working here for so long.

Many customers recognise that we’re a small and local business which is important to them.

When they walk into the business, they feel it has character, heart and shared values about what we’re trying to achieve. The community has really embraced us not because we’re a family business per se, but because we’re a business that cares about the community.

And I share a passion with my uncle for making beautiful things. I love seeing the look on customers’ faces when you return the thing that they’ve put so much heart and soul into, and you get to see their reaction.

There’s something really rewarding about creating something physical and being able to go home at the end of the day and say, “I made that thing over there” as opposed to writing a report or having a bunch of meetings.

Making a book is quite a process from start to end.

Most of the work in writing a book is done before it gets to us.

Once it gets to us, we take it over to the computer and figure out how to bind it. If we’re section sewing the book, we might print it in nested saddle stitch booklets. Those go through our printing press after we proof the file.

From there, the booklets go upstairs to Kelly who folds and collates the sections into a book block. She takes it to the sewing machine and sews it together. The book block then goes to the bench to be glued-up, end-papered and calicoed on the back, before being set aside to dry.

In the meantime, someone will size up the case, cut boards and cloth for the book block and make the cover. It will be checked against the book block to make sure that it’s the right size. If there’s any embellishment on the cover it will go on for foil stamping or printing. We make all of our own foiling plates in-house and do all of our foil stamping. Then you apply the embellishments to the cover before it goes onto the book block. The book block gets trimmed, then we glue the book block onto the case and leave it under weights until it dries.

If we’re lucky, that can all be achieved in about 24 hours. If we’re doing hundreds or thousands of books – like we might do for the Victorian court services – that can take two months to do. There’s many steps, but each of the steps depend on what the job is, and the product we’re making.

Each job is different, and a large part is thinking about how you’re going to get to the end and working backwards so you understand every step.

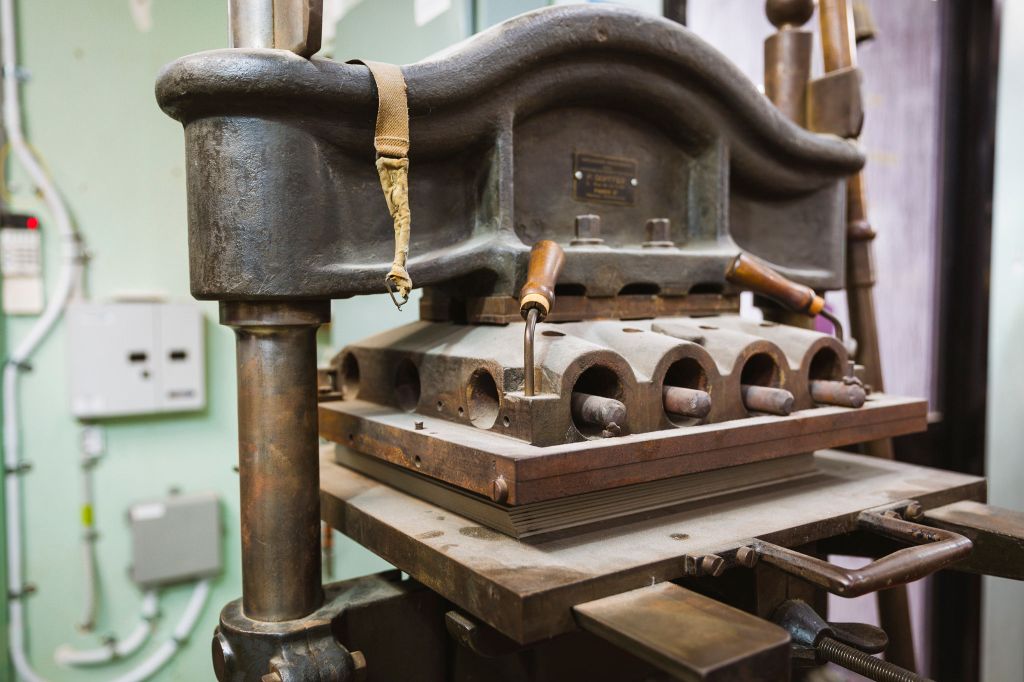

One of the unique things about the business is that we really married the old with the new.

We’ve got the old craft – doing handbook binding – which is combined with advanced, cutting edge technology. This allows us to create things that you couldn’t do with only one or the other. Regularly, I get phone calls from people and they ask, “do you do this?” The answer is almost always yes because we are able to do so many different things.

In some ways, the business name sells us short as far as what the business represents and what it can do. If someone wants to produce an album design that involves a laser cut, that prompts us to buy a laser so we can produce that sort of thing. We’re guided by the market as far as how the business has diversified.

Our job isn’t necessarily just to make books, but to execute someone else’s vision.

As far as nostalgia goes there’s still people that make a go of bookbinding as a hobby.

People refer to them as garage bookbinders and backyard bookbinders.

It’s exactly what you would imagine when you hear the term hand bookbinder – sewing, cutting and gluing things by hand and using tools. My uncle speaks fondly of the time he was able to buy his first sewing machine, because it allowed him to mechanise some of the processes.

We still do that. We have tools that are over 100 years old, but there’s a reason some of those tools have been superseded. It’s because – in certain instances –the new ones generally allow us to do a better and more consistent job. I think that’s benefited us in the long run.

But there are certainly still aspects that harken back to the origins of the business. There’s drawers of brass type and a machine for setting hot lead. Some of the best machines we have are some of the oldest machines we have because they don’t make them that way anymore.

The business benefits from new investments, and those that were made ages ago.

I think the most rewarding projects are the ones that customers are really passionate about and come from the heart.

Many those have been children’s books – people putting them together or rebinding a book from their childhood to give to their children. It can be emotional, and to be able to share in that is rewarding.

You get similar experiences with family histories because so much work goes into digging up all that information and putting it onto paper. It’s not the same reading it in a Word Document. There’s something to be said for a product that’s produced and packaged nicely. Our work adds value and is typically cherished.

What brings me to work every day is the relationship I have with customers and coworkers. There’s always new technology and machinery, and the digital revolution has affected us positively and negatively. While people need fewer things printed and written, the tools that people have access to now provide great opportunities to create, which we can then bind into physical products.

And paper has been shown to be one of the most reliable forms of storage throughout history.

COVID-19 was a pretty tough time for everyone.

This business included.

We were permitted to remain open as we are part of the print industry, which was deemed an essential service. We shortened shifts and we had some people working from home, but we fought through. Now that we’re reemerging, we’re seeing a bit of a backlog of projects that people had put on hold. A lot of real estate work is coming back. We do menu covers for restaurants and we’re starting to see big orders for those coming through now that they have opened up again.

A byproduct of the last year is it gave people time to work on personal projects. People have spent time writing memoirs, family histories, photo-books, wedding albums and so on. They bring them to us to print and bind. In some ways that’s been a silver lining.

I’ve heard from our customers that they’re really happy that we’re a local business. There’s still something to be said for going around the corner to your local bookbinder.

I certainly wouldn’t say it’s been a net benefit, but there have been things that we’ve benefited from that wouldn’t have happened were it not for the events of last year.

I can’t predict where we’re going to be in five or 10 or 15 years.

Things change so quickly with new technology, processes and the environment that we’re operating in.

But I am confident that we’ll still be here.

As for what sort of things we’re actually going to be doing, I’m sure it’ll involve quality, craft and probably paper.

But what we will be making will be led by our customers.

Written by Aron Lewin, with all images by Tatiana C.C. Scott.

talesofbrickandmortar@gmail.com